From Farm To Fridge :

A Delicous Journey

2009 - FRESH BEGINNINGS

Shri Krishna Farms launched its operations in Wada, Maharashtra with a vision of providing hygienic and healthy milk to the people of India. We were one of the few pioneers in the country who believed in milking animals in a safe and hygienic environment. We kept in the most sanitary conditions with provisions for temperature and humidity control, unlike the unsanitary conditions prevailing in commercial dairy farms

2013 - EMBRACING CHANGE

As we grew, we realized the need to evolve. We dismantled our partially automated farm and started procuring milk from local farmers. This allowed us to continue our supplies and support the community.

2014 - COMMUNITY BUILDING

We established milk collection centers in Wada, which provided livelihood to over 500 farmers in the area. We believe in supporting our community and ensuring their well-being.

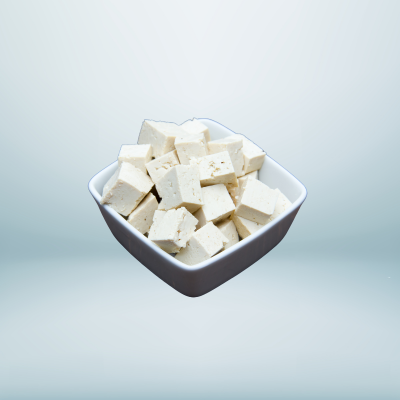

2015 - A MASSIVE COTTAGE

Our love for dairy led us to establishing a Paneer manufacturing plant in Wada. What started as a small manual setup, is now a fully automated facility with a daily capacity of 20 MTPD. Our aim is to be one of the most advanced Paneer manufacturing units in the country.

2016 - GREEK GOODNESS

We started co-manufacturing Greek Yogurt for Epigamia. Initially it was just 200 cups a day and now, we have a production capacity of 1 lakh cups per day! With our use of cutting-edge technologies and rigorous hygiene practices, we're able to make products with long shelf life without using any preservatives.

2021 - SUSTAINABLE WHEYS

The liquid that separates from milk while making paneer...is whey! And since we've always been conscious of our impact on the environment, we set up our own whey powder plant with a capacity of 3MT per day. This ensures that our business has the least possible environmental footprint while improving our efficiencies.

2022 - CHEESING IT UP

Constantly innovating, we thought what else could we bring to the table? And that's when the idea of commencing a state-of-the-art production facility in Wada for cheese manufacturing arose. Now, we're all set to spread happiness!

2023 - CULTIVATING COLLABORATIONS

We collaborated with ID Fresh for bringing paneer and curd to the shelves. We believe that partnerships are crucial for success and we're excited to grow with them.

2024 - INCREASING THE DELICIOUSNESS 2X

Another step of expansion with Frozen Paneer for the international market. We use state-of-the-art IQF technology to ensure the best quality of freezing of paneer. Our frozen paneer cubes are made from pure and best quality milk so that you get that essential punch of nutrition in your diet.

No Waste, All Taste Dairy :

Keep A Low Environmental Footprint

We strive to minimize waste and maximize taste in our production process.

ACTION :

- Zero-waste production model

- Local sourcing and byproduct repurposing

- Zero-discharge dairy plant

- Water harvesting techniques

- 300KW solar plant, soon to be expanded to 600KW

- Whey powder plant

- ETP for water treatment

IMPLEMENTING SUSTAINABLE PRACTICES AT SHRI KRISHNA FARMS

IMPACT :

- 4 lac kg of CO2 emissions reduced annually, equivalent to planting 20,000 trees!

- 1,00,00,000 liters of water harvested annually

- 80,000 liters of whey per day processed, reducing 5x more pollution than sewage water

- No need to release water outside our premises due to ETP treatment

- Reduced environmental footprint and commitment to sustainability

- In addition to our sustainable practices, we also, prioritize quality in our production process, using homegrown technology and pursuing quality as a never-ending journey

- By focusing on taste and sustainability, we believe we are contributing to a healthier and more sustainable future for all